Bottom Camera Position (Video Guide)

Now that we know the offset from the top camera to the nozzle, we can use the nozzle to set our bottom camera position.

-

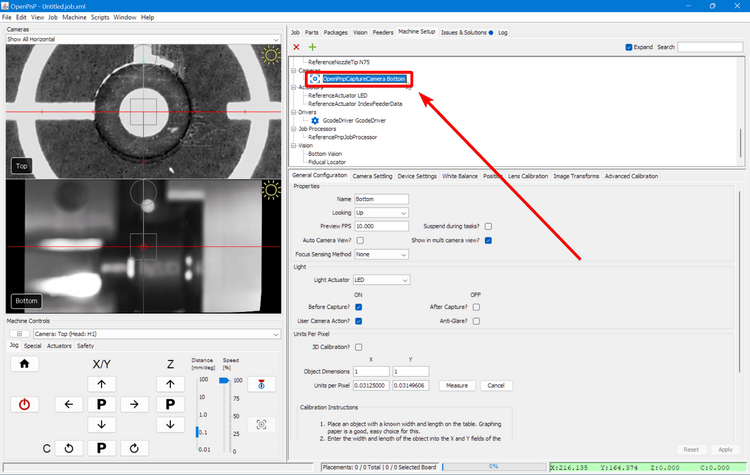

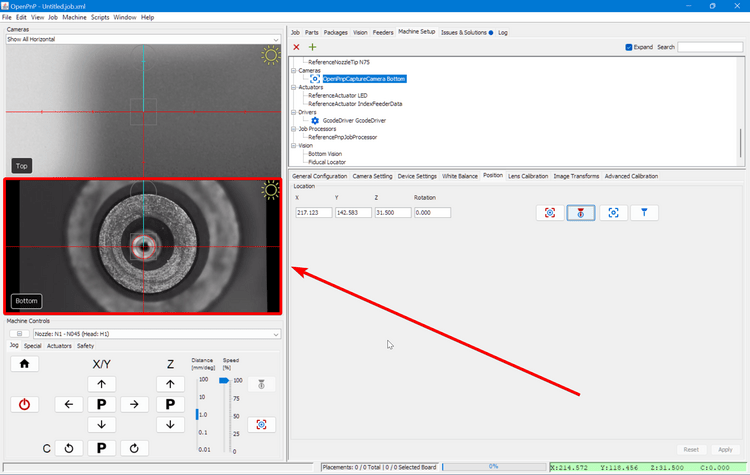

Navigate to

Machine Setup > Cameras > OpenPnpCaptureCamera Bottom. -

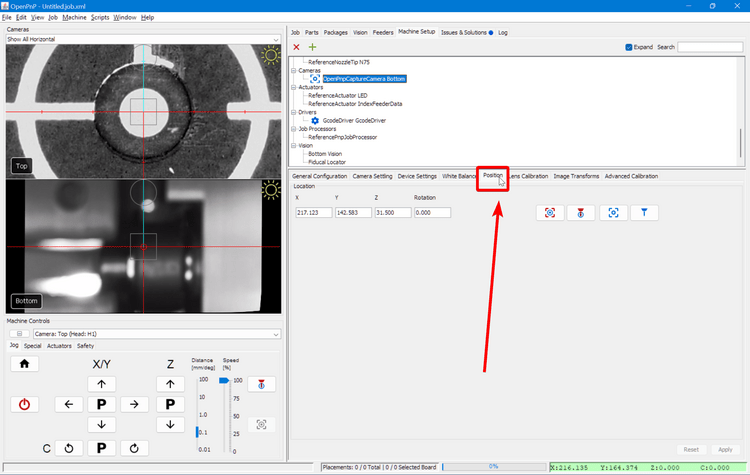

Click on the

Positiontab. -

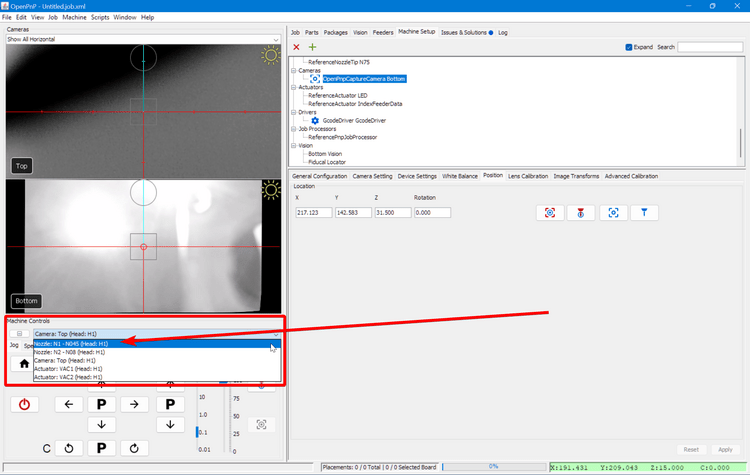

Select the

Nozzle: N1from the machine controls dropdown. -

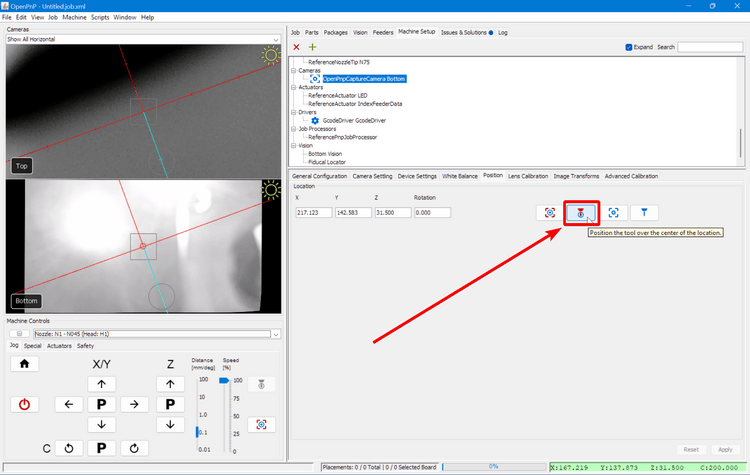

Click the "Position tool over location" button to bring the left nozzle roughly above the bottom camera.

-

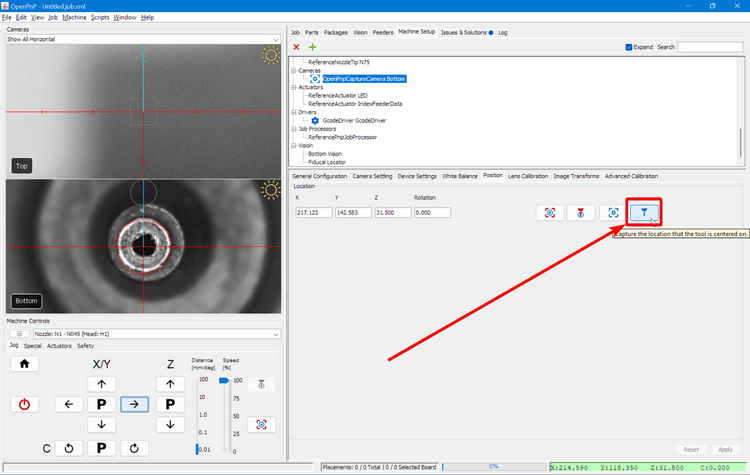

Jog the toolhead until the left nozzle is directly in the center of the bottom camera's vision.

-

Click the "Capture Toolhead Location" button to calculate the correct position for the bottom camera. Make sure your Z height is at 31.5. If it isn't, manually enter

31.5into the Z field. -

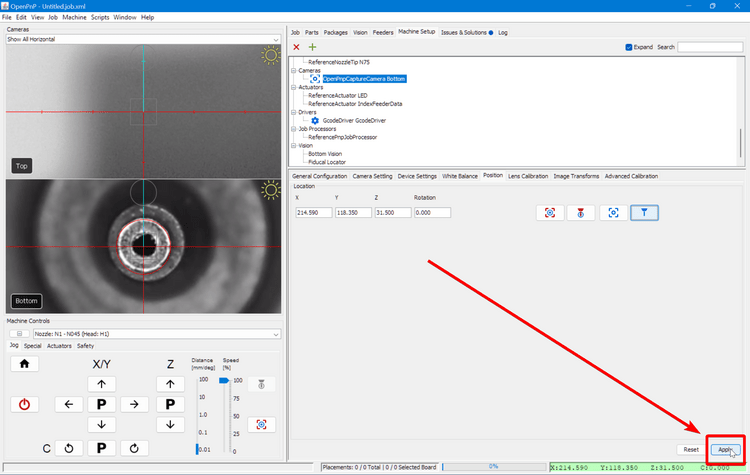

Click the

Applybutton to save the new camera position.

Next Steps

Next is Nozzle Tip Calibration.